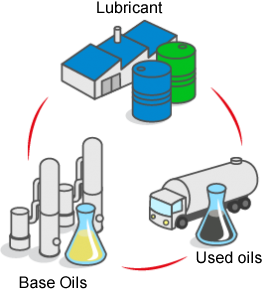

Osilub, thanks to its patent protected process “thin-film vacuum distillation”, offers quality regenerated petroleum products with favorable environmental, economic and social impacts.

A state-of-the-art process: thin film vacuum distillation preserves oil molecules; the oil molecule is heated to 360 ° C (680 ° F) for 0.5 seconds, which prevents cracking.

By treating an additional 120,000 tons of used oil every year, OSILUB responds to a sustainable development issue in accordance with European Directive 2008/98 / EC of 19 November 2008 which stipulates the priority of recycling.

The thin film vacuum distillation process allows:

- Elimination of more than 10% of waste

- Diesel recycling

- Production of 100N and 150N base oil and 935 fluxing agent.

Processing capabilities

- 120,000 tons of used oil per year

Capacité de production par an

- SN 100: 25,740 tons

- SN 150: 52,260 tons

- 935: 24,000 tons

- Diesel: 6,000 tons

Osilub ensures the quality of finished products through multiple controls

At entry and exit: thorough quality control of raw materials and regenerated materials meeting precise specifications

Environmental efficiency

The configuration of the plant allows the protection of soil, surface and water, optimization of the energy consumed and the collection and systematic treatment of waste.